Fourth Manufacturing Revolution Industry 4.0

Manufacturing Revolution Industry 1.0 to Industry 4.0

What is manufacturng Industry 4.0 ?

Fourth Manufacturing Revolution Industry 4.0

Industry 4.0 refers to the fourth industrial revolution. The term represents the role that cyber-physical systems (CPS), cloud computing, and IIoT (industrial internet of things) will have on manufacturing processes.

Industry 4.0 is a new manufacturing approach which seamlessly integrates into production systems & facilities all advanced technologies (including Internet of Things (IoT), cloud computing and analytics, and AI and machine learning), information systems(analytics), international best practices as well as an organizations own classified parameters & all this being applied while on the move whether it is manufacturing or supply chain management or customer service.

These manufacturing facilities use cutting edge technology like robotics, sensors & software to reduce wastage, increase insights into operations thereby rising up the value chain. Increased digitalization can help increase automation and process improvements & optimization, in turn achieving efficiency and responsiveness not earlier possible.

Scalability & reduced downtime separates today’s manufacturing with that of bygone era. Fourth industrial revolution is about analyzing big data across geographies collected through advanced technologies, timely analyzing information, predicting and performing maintenance with minimum human intervention in nick of time to keep maintenance costs at a possible minimum.

High-tech IoT devices in mega smart factories increases productivity and quality. Replacing manual inspection with AI-powered visual insights reduces manufacturing errors and saves money and time. With minimal investment, smartphone can be connected to the cloud to monitor manufacturing processes remotely. By machine learning, manufacturers can detect errors early, rather than at later stages when repair work is more expensive.

Industry 4.0. Revolution with its unprecedented speed and scale allows a more data-driven approach to operations. This data, pulled from your assets, adds value and enables smarter decisions. As you integrate more assets into business workflows, along with technologies like 5G and edge computing, your challenge becomes uncovering what matters – finding the right insights, at scale. In the midst of this unusual and global disruption, these insights can be a vital key to operational resilience.

Uses of industry 4.0

Uses in industry

Industry 4.0 concepts and technologies can be applied across all types of industrial companies, including discrete and process manufacturing, as well as oil and gas, mining and other industrial segments.

Industrial Manufacturing Revolution Types

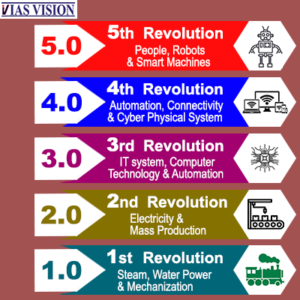

Industrial Revolution Types:

- 1st industrial revolution– Steam and water power are used to mechanize production

- 2nd industrial revolution – Electricity allows for mass production with assembly lines

- 3rd industrial revolution– IT and computer technology are used to automate processes

- 4th industrial revolution (Industry 4.0)– Enhancing automation and connectivity with CPS

- 5th industrial revolution (Industry 5.0) --The term Industry 5.0 refers to people working alongside robots and smart machines. It's about robots helping humans work better and faster by leveraging advanced technologies like the Internet of Things (IoT) and big data. It adds a personal human touch to the Industry 4.0 pillars of automation and efficiency.